Truebird Automated Coffee Kiosk, First Generation

CLIENT: Truebird

OUR ROLE: Industrial Design, Mechanical Engineering, Automation Design

Truebird began with the mission to bring high-quality specialist coffee to spaces it had not been before. Before engaging with Hypersurface Studio, the team had an innovative way to avoid the typical use of robot arms and a solid (and tasty!) coffee program, but was not ready to deal with the challenges of existing in the real world and serve coffee without a human present. Also, the machine had to be compelling enough to convert customers to spend premium money on a premium product in a category that was known for being anything but premium. As a fresh startup, they were racing against the clock to bring a viable prototype before investors to secure their future.

RESULTS

Thousands of cups of coffee served autonomously

Near-universal praise amongst customers

Attained $14m company valuation

Contracts in three large commercial buildings in Manhattan

What we did:

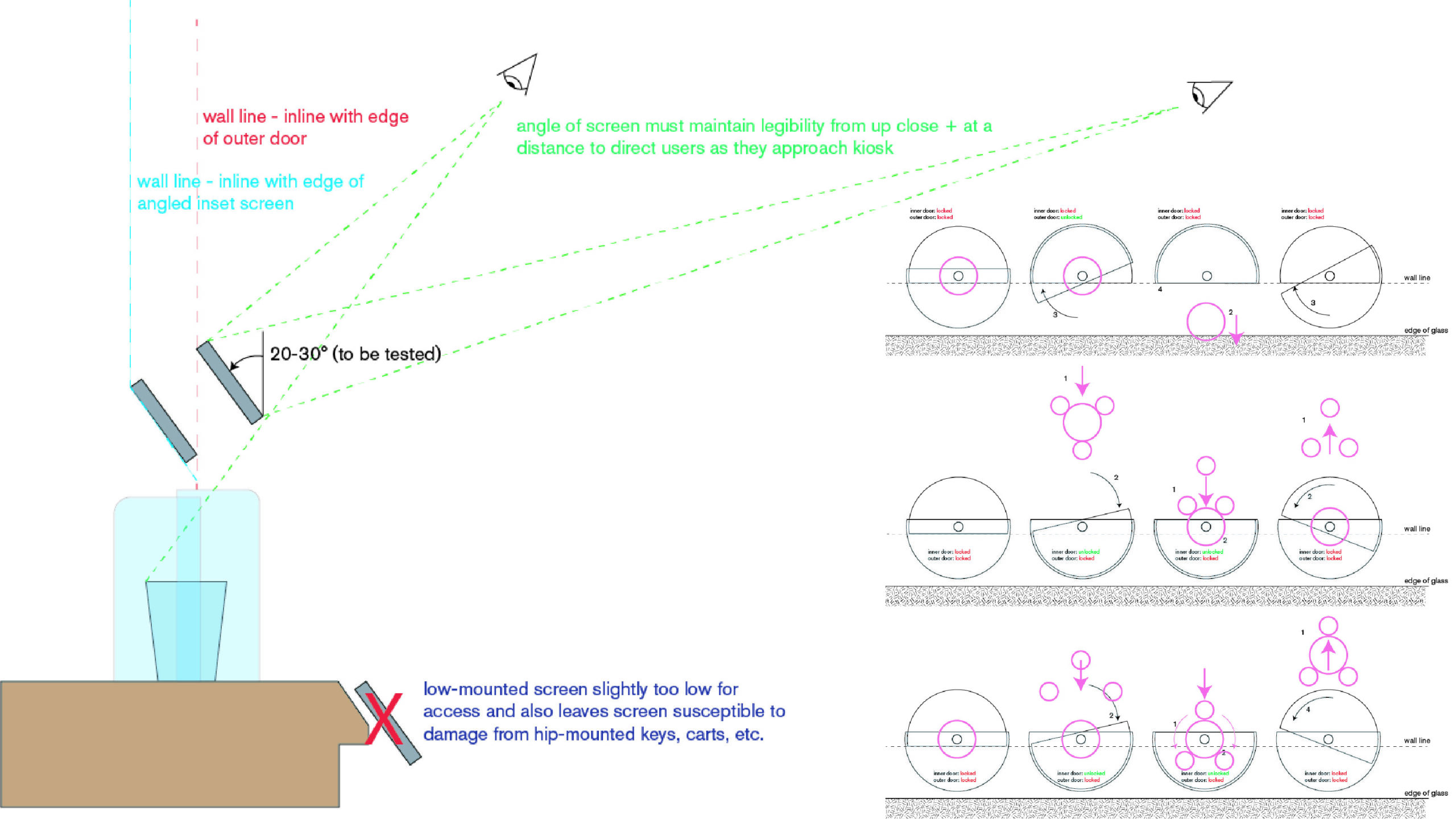

- Conducted research and user testing with prototype human-robotic interactive interfaces

- Designed a secure, elevated, and approachable physical and digital user interface that served the needs of every user, from customer to service technician

- Devised a system of robotic-human interaction that brought industrial-level robotic safety to a human, customer-facing scale.

- Achieved certification for food service in NYC, where standards are most stringent

- Utilized simulation and real testing to ensure the machine would withstand real world use and provide a lengthy service life.

INTERACTION DESIGN

The challenge that Truebird was focused on overcoming was the adoption of robotics in food service. Traditionally, these two fields have existed in opposite spaces, with robotics occupying industrial spaces and food in hospitality spaces. In order to bring robotics into hospitality spaces, we would have to understand what has made them fundamentally incompatible.

In industrial spaces, robots are physically separated from humans by barriers and are disabled when a human is present, either by manual lockout procedures or by sensors that trigger a shutdown when a person is detected. For this machine, where people interact directly with an autonomous automated system, our challenge was to make the system not only safe, but approachable.

Predictability in motion became our focus. Intention of action is easier to understand when degrees of freedom (DOF) are eliminated. A 6 DOF robotic arm can move in an infinite amount of ways, but a 1 DOF door can only move in one way. We designed the interface such that the limits of movement were instantaneously understood and predictable.

ENGINEERING

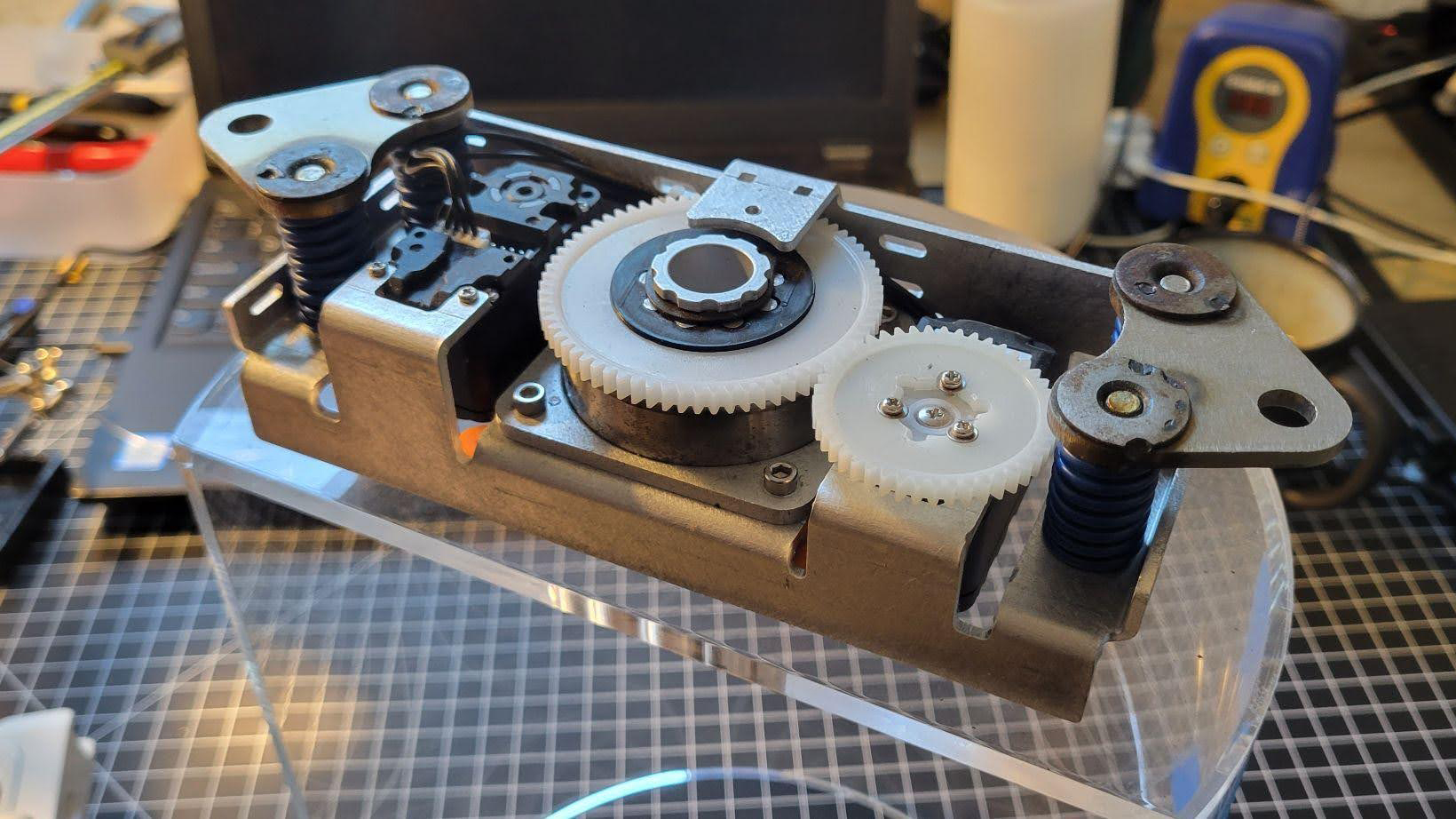

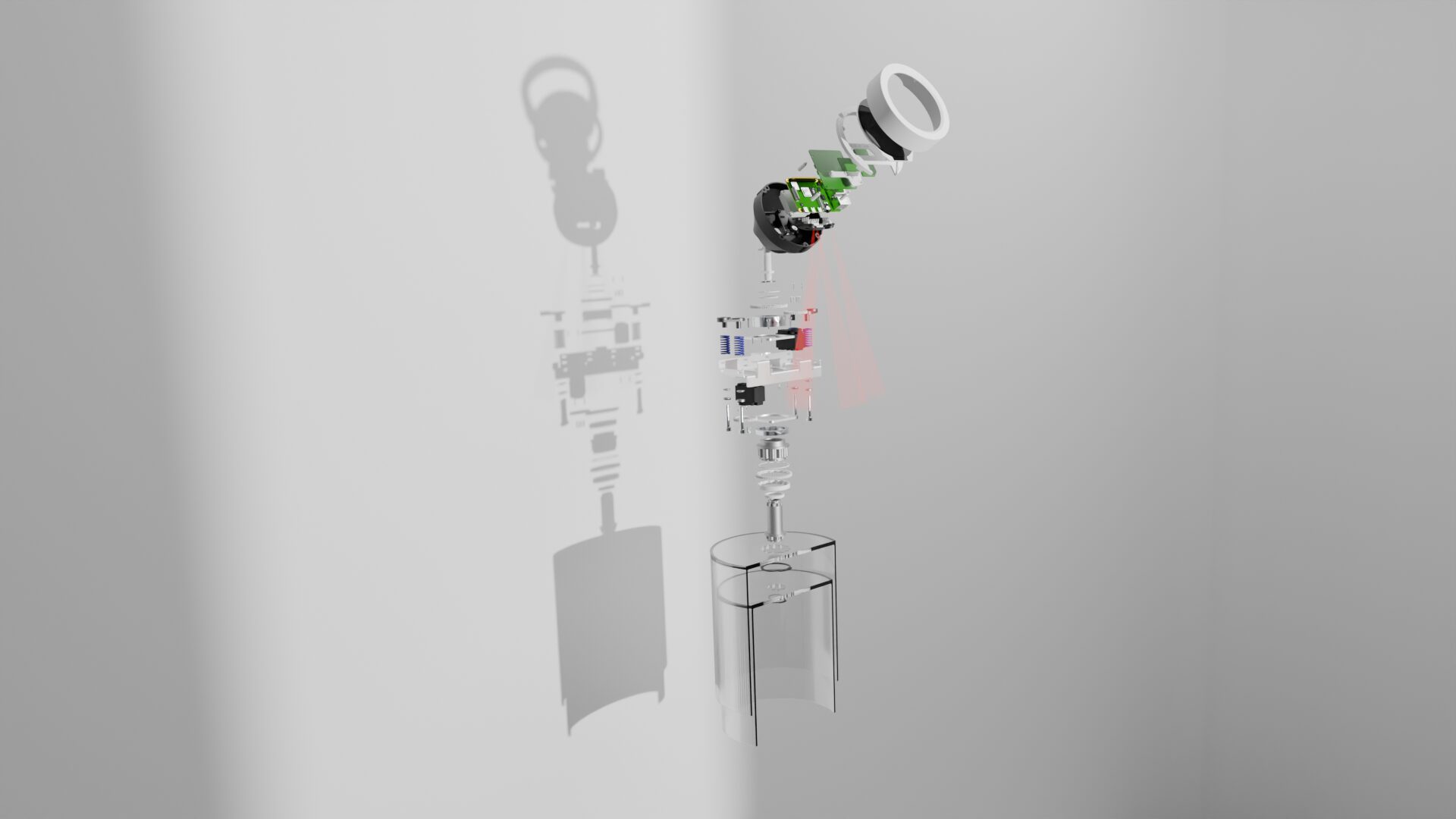

The elegance of the solution depended on a balance of the technical and aesthetic demands. The ideal solution was invisible. The next best solution was as small as possible, while still maintaining durability, serviceability and manufacturability.

In opposition to this goal, not only did we have to fit all of the necessary actuators to drive the interface, but more importantly, all of the sensors and on-board computing to give the system intelligence and keep people safe.

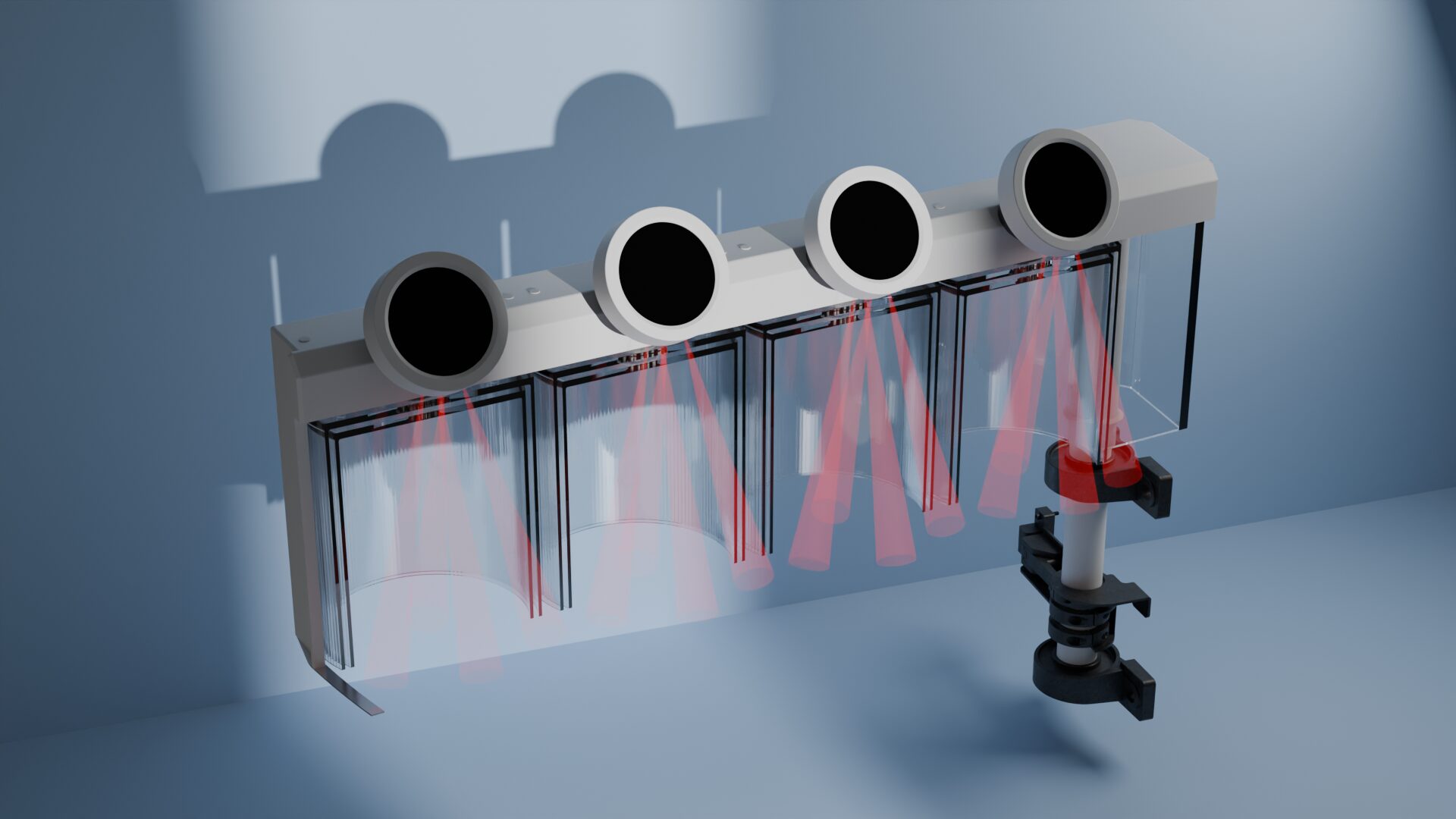

While other automated coffee machines are black boxes from which a cup of coffee emerges, the Truebird was designed to showcase the entire coffee brewing process in an appeal to authenticity, honoring their partnerships with local roasting companies that provided full documentation of their process.

The minimization of the customer pickup interface reflects this value. As it sits in the very front of the machine, every non-transparent part was made to be as small as possible to maintain visibility of the coffee making process. All of these parts were miniaturized while also using as many off-the-shelf components as possible to speed development and serviceability appropriate for the production scale.

Applying Industrial Design and Mechanical Engineering concurrently made it possible to fulfill all of these goals.